Fertilizer granulation is an important process in agriculture that involves the conversion of raw materials into granular fertilizer for use in crop production. Granulation not only improves the handling and storage properties of fertilizers but also enhances nutrient availability, reduces nutrient losses, and increases crop yield. Fertilizer granulators are the machines used for this process, and they come in various types and designs depending on the specific application and production capacity.

Types of Fertilizer Granulators

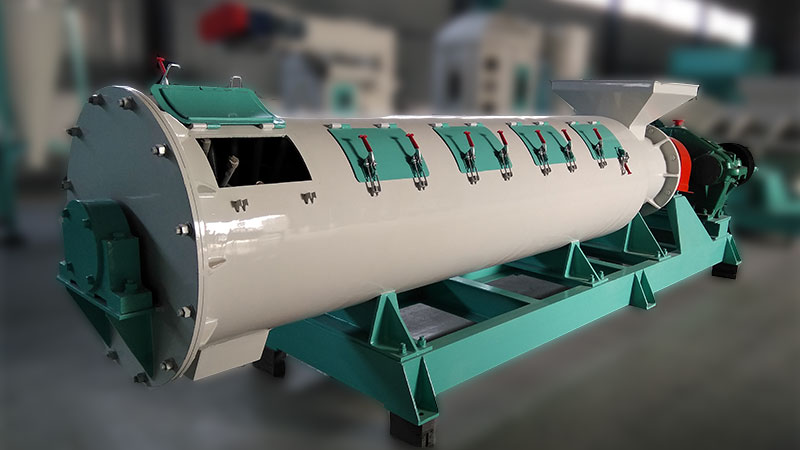

Rotary Drum Granulator is a commonly used granulator that utilizes a rotating drum to agglomerate raw materials into pellets. The drum is lined with a special rubber material to prevent corrosion and abrasion. The process involves mixing the raw materials with a binder and then feeding them into the rotating drum where they are agglomerated and sprayed with a liquid binder.

Disc Granulator uses a circular disc to agglomerate raw materials into pellets. The process involves feeding the raw materials onto the disc, which rotates at a specific speed. The rotation of the disc causes the material to agglomerate into small pellets, which are then dried and screened.

Double Roller Press Granulator is a compact machine that utilizes a pair of rollers to compress and agglomerate the raw materials into pellets. The rollers have a special design that ensures uniform compression and agglomeration of the raw materials.

Flat Die Granulator is a small and simple machine that utilizes a flat die to compress and agglomerate the raw materials into pellets. The die has several holes that determine the size and shape of the pellets.

How Fertilizer Granulators Work

The fertilizer granulation process involves several stages, including raw material preparation, mixing and granulation, drying and cooling, and screening and coating. The raw materials are first prepared by grinding, drying, and sieving to ensure a uniform size and moisture content. The materials are then mixed with a binder and fed into the granulator.

In the granulator, the materials are agglomerated into pellets using various mechanisms, such as rolling, compressing, or spraying. The resulting pellets are then dried and cooled to remove excess moisture and prevent clumping. The dried pellets are then screened to remove undersized or oversized particles and coated with a protective layer to improve their stability and prevent caking.

Advantages of Fertilizer Granulation

Fertilizer granulation offers several advantages over other forms of fertilizers. Firstly, granulated fertilizers have a higher nutrient availability and uptake by plants, compared to powdered or liquid fertilizers. The granules release nutrients slowly and uniformly, ensuring a steady supply of nutrients to the plants throughout the growing season. Secondly, granulated fertilizers are more resistant to moisture and other environmental factors, reducing nutrient losses and increasing fertilizer efficiency. Thirdly, granulated fertilizers are easier to handle, store, and transport, reducing labor and transportation costs.

Factors Affecting Fertilizer Granulation

Several factors affect the granulation process, including raw material properties, granulator design and operation, moisture content and temperature, and additives and binders. The properties of the raw materials, such as particle size, shape, and density, influence the flowability and agglomeration behavior of the materials. The design and operation of the granulator affect the size, shape, and density of the pellets. The moisture content and temperature of the materials affect the drying and cooling rates, as well as the final product quality. Additives and binders can be used to improve the agglomeration behavior, reduce dust formation, and enhance the nutrient release properties of the fertilizers.

Maintenance and Troubleshooting

To ensure optimal performance and prolong the lifespan of fertilizer granulators, regular cleaning and inspection are necessary. Common problems in granulation

include equipment wear and tear, blockages in the granulator, uneven granule size, and caking of the fertilizer. These issues can be resolved by adjusting the machine settings, replacing worn-out parts, or using appropriate additives and binders. Operators should also observe safety precautions such as wearing protective gear, following operating procedures, and avoiding overloading the granulator.

Conclusion

Fertilizer granulation is an essential process in modern agriculture that improves the efficiency and sustainability of crop production. By converting raw materials into granular fertilizers, farmers can ensure a steady and controlled release of nutrients to the plants, reducing nutrient losses and increasing yields. With various types and designs of fertilizer granulators available, farmers can choose the most appropriate machine for their specific needs and production requirements. Regular maintenance and troubleshooting of the granulators can ensure their optimal performance and prolong their lifespan, contributing to the long-term success of agricultural production.